infrastructure

MANUFACTURING FACILITIES

A production facility spanning approximately 10,000 sq. mtrs. is distributed across 3 units located in Pune, which is renowned as a prominent centre for engineering and information technology in India. An advanced manufacturing facility equipped with a wide range of state-of-the-art, high-tech machinery, complemented by Best-in-Class Inspection Facilities. Further enhancing the manufacturing capabilities, the company have 2 more group companies which includes a Foundry located in Kolhapur, Maharashtra, and a Plant in Rajkot, Gujarat including Group Companies.

PLANT 1

PLANT 2

PLANT 3

OVERVIEW OF FACILITIES

5-Axis Turn Mill Machining Centers

Make : MAZAK, DMG MORI, EMAG

Max. Diameter 250MM

9 Nos.

Turning Centers

Make : MAZAK, TSUGAMI, LOKESH, JYOTI, BFW

Max. Diameter 300 MM

19 Nos.

Vertical Turret Lathes

Make : HYUNDAI, ACE, BFW, JYOTI

Max. Diameter 600 MM

6 Nos.

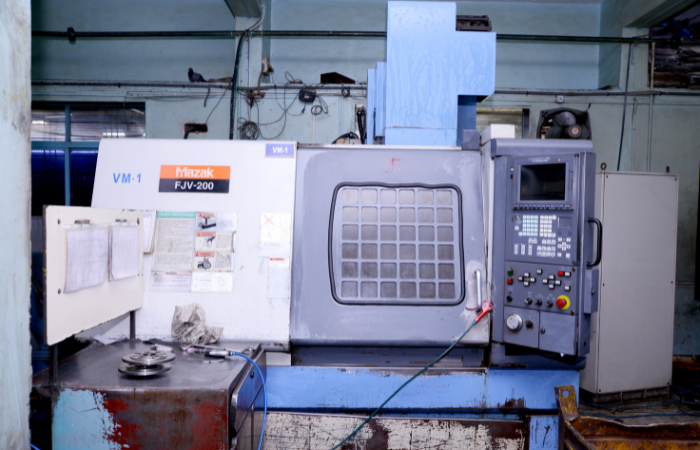

Vertical Machining Centers

Make : MAZAK, MAKINO, ACE, BFW, JYOTI, LOKESH

Scope : UPTO 800MM

14 Nos

5-Axis Horizontal Machining Centers

Make : GROB

UPTO 600MM

1 Nos.

Horizontal Machining Centers

Make : MAZAK, DMG, OKUMA, JYOTI

UPTO 1450MM

22 Nos.

Co-Ordinate Measuring Machines

Make : MITUTOYO, RENISHAW

X,Y,Z : 900X2000X800 or 300X300X400

4 Nos.

SMART FACTORY

Our smart factory offers a multitude of advantages that can revolutionize the way a manufacturing business operates. By embracing cutting-edge technologies, such as the Internet of Things (IoT), artificial intelligence, and automation, a smart factory can significantly enhance operational efficiency.

Real-time data collection and analysis enable us with better decision-making, predictive maintenance, and quality control, reducing downtime and minimizing errors. The interconnected machinery and systems in a smart factory communicate seamlessly, allowing for rapid adjustments in production to meet shifting market demands. Moreover, the ability to remotely monitor and manage operations can lead to cost savings and increased sustainability. In essence, a smart factory not only transforms production processes but also positions a company to remain competitive and adaptable in an ever-evolving industrial landscape.

SMART FACTORY

Our smart factory offers a multitude of advantages that can revolutionize the way a manufacturing business operates. By embracing cutting-edge technologies, such as the Internet of Things (IoT), artificial intelligence, and automation, a smart factory can significantly enhance operational efficiency.

Real-time data collection and analysis enable us with better decision-making, predictive maintenance, and quality control, reducing downtime and minimizing errors. The interconnected machinery and systems in a smart factory communicate seamlessly, allowing for rapid adjustments in production to meet shifting market demands. Moreover, the ability to remotely monitor and manage operations can lead to cost savings and increased sustainability. In essence, a smart factory not only transforms production processes but also positions a company to remain competitive and adaptable in an ever-evolving industrial landscape.

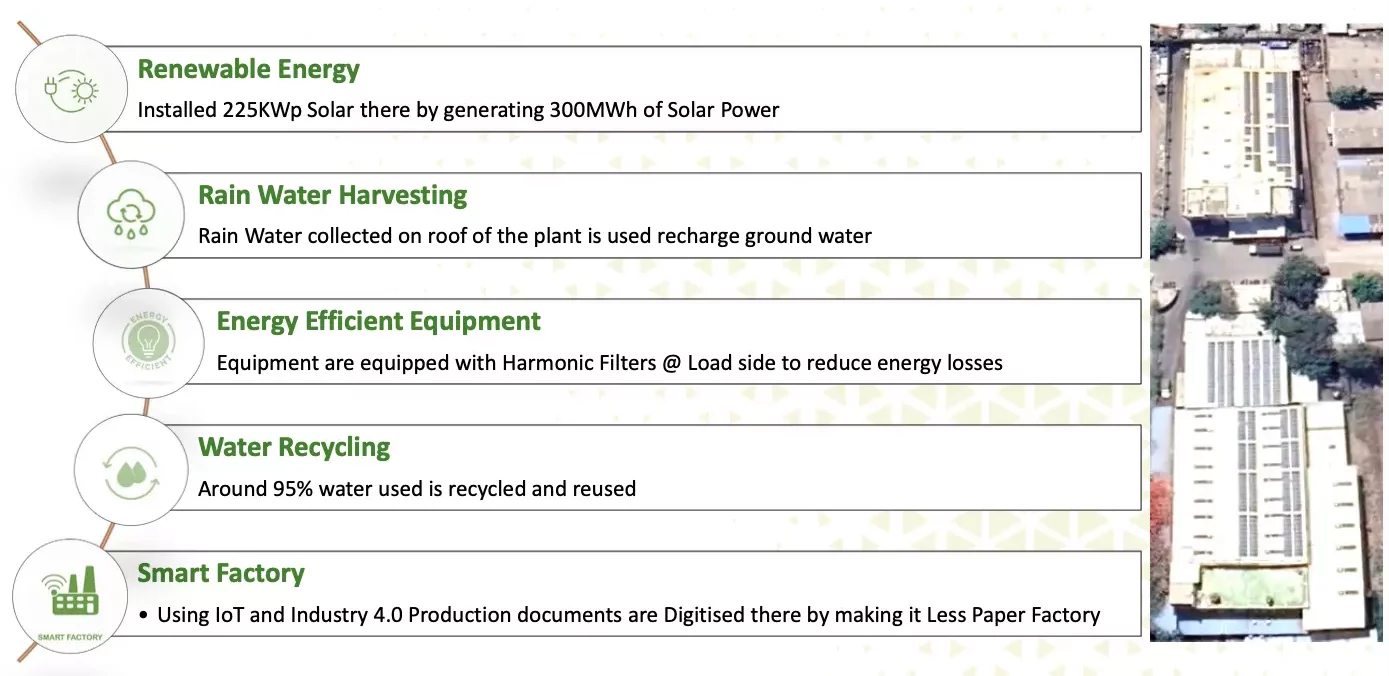

SUSTAINABLE MANUFACTURING

Renewable Energy

Installed 225KWp Solar there by generating 300MWh of Solar Power

Rain Water Harvesting

Rain Water collected on roof of the plant is used recharge ground water

Energy Efficient Equipment

Equipment are equipped with Harmonic Filters @ Load side to reduce energy losses

Energy Efficient Equipment

Equipment are equipped with Harmonic Filters @ Load side to reduce energy losses

Water Recycling

Around 95% water used is recycled and reused

Water Recycling

Around 95% water used is recycled and reused

Smart Factory

using loT and Industry 4.0 Production documents are Digitised there by making it Less Paper Factory